OpenPLC Editor for CONTROLLINO

Introduction In the world of industrial automation, having an intuitive and powerful programming environment is key. OpenPLC Editor, combined with CONTROLLINO, brings a seamless IEC

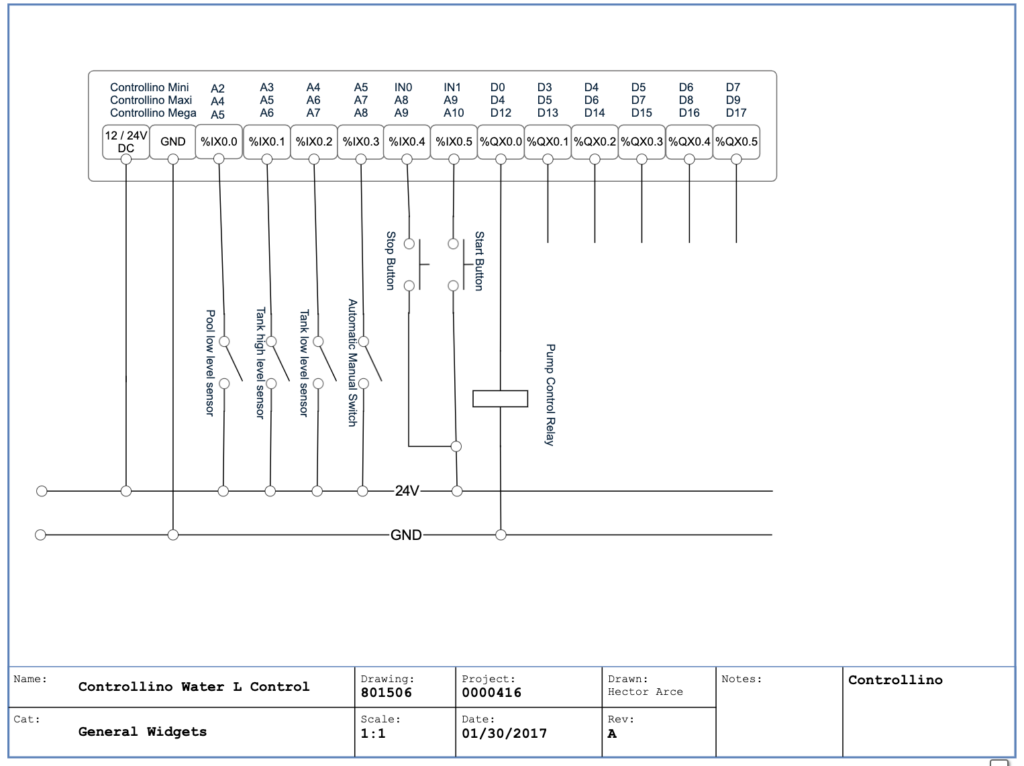

This tutorial explains how to implement an automatic water reserve control system using a CONTROLLINO PLC and OpenPLC. The system monitors the water levels of a cistern (minimum level) and an elevated tank (minimum and maximum levels) to control a pump that transfers water from the cistern to the elevated tank. Additionally, manual pump control is possible using start and stop buttons.

Before starting, ensure you have the following:

Define the following inputs and outputs in your ladder logic program:

| Name | Type | Description | Pin |

|---|---|---|---|

Pool_Low_Level_Sensor | BOOL | Indicates the minimum water level in the cistern. | %IX0.0 |

Tank_High_Level_Sensor | BOOL | Indicates the maximum water level in the tank. | %IX0.1 |

Tank_Low_Level_Sensor | BOOL | Indicates the minimum water level in the tank. | %IX0.2 |

Automatic_Manual_Switch | BOOL | Switch for selecting automatic or manual mode. | %IX0.3 |

Stop_Button | BOOL | Push button to stop the pump manually. | %IX0.4 |

Start_Button | BOOL | Push button to start the pump manually. | %IX0.5 |

Water_Pump | BOOL | Output controlling the water pump. | %QX0.0 |

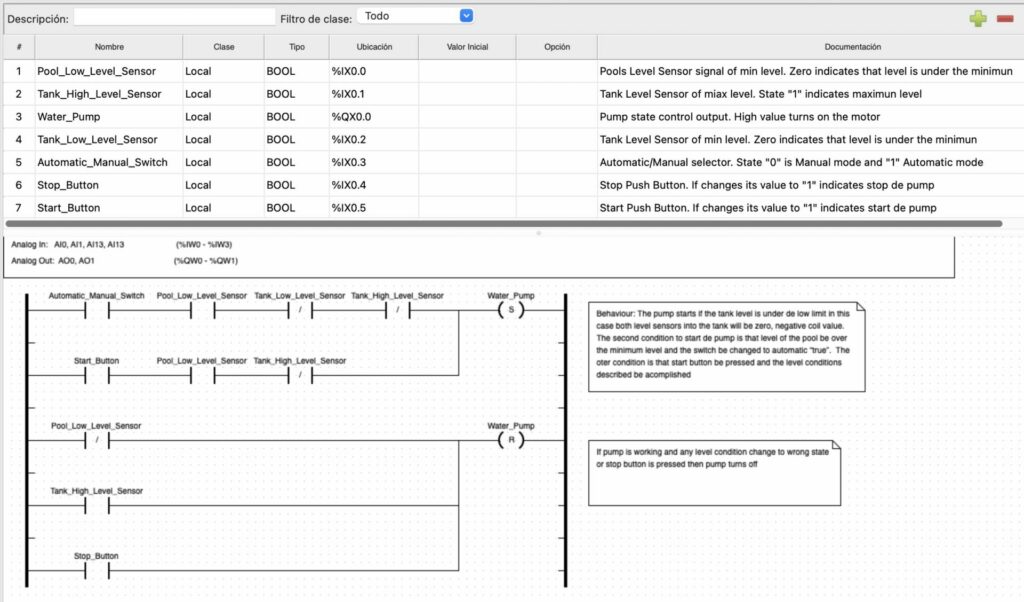

Water_Pump) is activated automatically when:

Pool_Low_Level_Sensor is active).Tank_Low_Level_Sensor is active).Tank_High_Level_Sensor is active).Pool_Low_Level_Sensor is inactive).Start_Button) activates the pump.Stop_Button) deactivates the pump.Automatic_Manual_Switch) must be in manual mode to enable this functionality.Automatic_Manual_Switch toggles between automatic and manual modes.

Automatic_Manual_Switch.

Pool_Low_Level_Sensor and Tank_Low_Level_Sensor are active, the pump (Water_Pump) turns on.Tank_High_Level_Sensor is active (tank full).Pool_Low_Level_Sensor is inactive (cistern empty).Start_Button turns on the pump manually.Stop_Button turns off the pump manually.Congratulations! You have successfully implemented a water reserve control system with both automatic and manual modes. This system is ideal for efficiently managing water levels in elevated tanks and cisterns. You can further customize the system by adding additional sensors or modifying the logic to suit specific requirements.

Introduction In the world of industrial automation, having an intuitive and powerful programming environment is key. OpenPLC Editor, combined with CONTROLLINO, brings a seamless IEC

The project provides an easy to install tool to test the main features of the Controllino MICRO by serving an embedded web application directly from