OpenPLC Editor for CONTROLLINO

Introduction In the world of industrial automation, having an intuitive and powerful programming environment is key. OpenPLC Editor, combined with CONTROLLINO, brings a seamless IEC

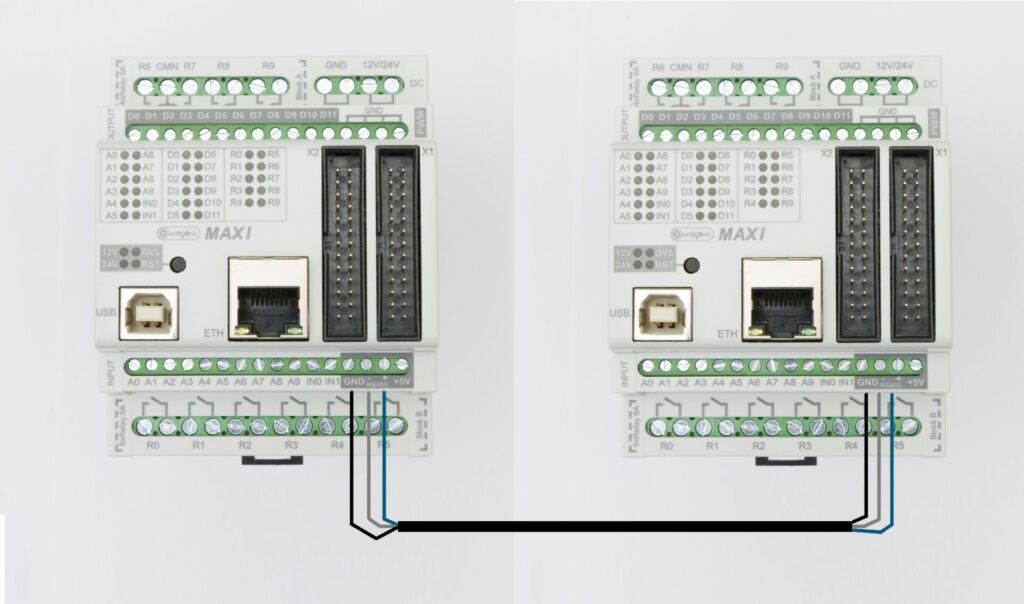

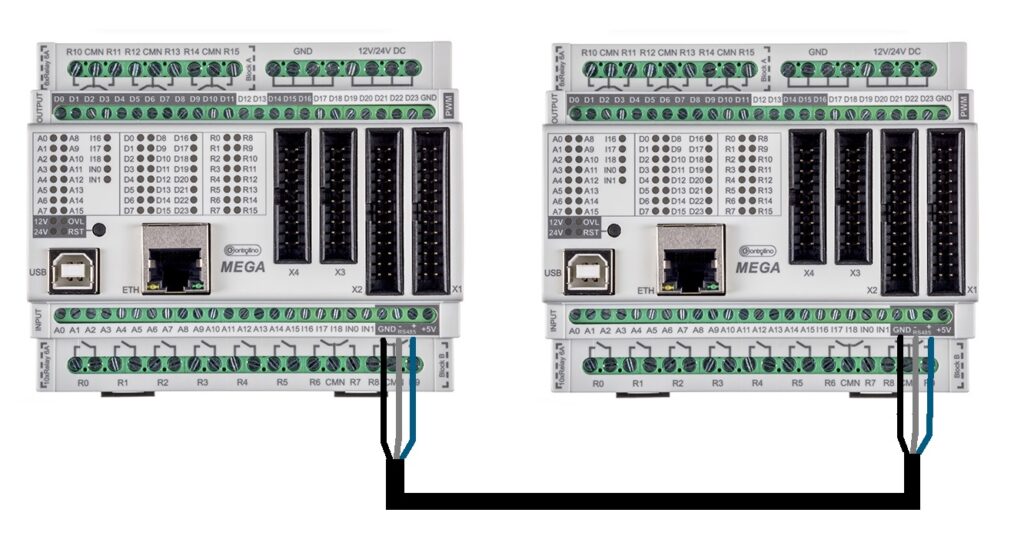

This tutorial will guide you through setting up Modbus RTU communication between a master and a slave device using two CONTROLLINO devices. The master device reads digital and analog inputs from the slave and sends data to control its outputs, while the slave responds with data controlling its own outputs based on commands received from the master.

The Controllino BSP, for MAXI and MEGA, inside pins_arduino.h contains the following definitions:

// ArduinoRS485 library support

#define RS485_SERIAL_PORT Serial3

#define RS485_DEFAULT_TX_PIN 14

#define CUSTOM_RS485_DEFAULT_DE_PIN 75

#define CUSTOM_RS485_DEFAULT_RE_PIN 76These allows the use of the default instance of RS485 library:

RS485Class RS485(RS485_SERIAL_PORT, RS485_DEFAULT_TX_PIN, RS485_DEFAULT_DE_PIN, RS485_DEFAULT_RE_PIN);Which is also the default RS485 interface for ModbusRTUServer and ModbusRTUClient the default instances for RTU in ArduinoModbus library.

This allows an easy integration of the libraries and the Controllino BSP so there is not need to create an instance of RS485 and later an instance of ModbusRTUServer or ModbusRTUClient, but just use the default instances like in the library examples.

You can download the example Modbus RTU master and slave code from the following GitHub repository:

ModbusRTUClient.begin(9600) for the master and ModbusRTUServer.begin(1, 9600) for the slave. This sets up the master to communicate at a 9600 baud rate, and the slave is assigned ID 1.Serial.begin(9600).CONTROLLINO_A0 to CONTROLLINO_A10 as inputs.CONTROLLINO_R0 to CONTROLLINO_R10 as outputs.CONTROLLINO_A11 to CONTROLLINO_A15 as inputs.CONTROLLINO_D0 to CONTROLLINO_D4 as outputs.In the loop() function:

CONTROLLINO_A0 to CONTROLLINO_A10) on the master.ModbusRTUClient.coilWrite(). This will send the master’s inputs to the corresponding digital outputs (CONTROLLINO_R0 to CONTROLLINO_R10) on the slave.In the loop() function of the slave:

ModbusRTUServer.poll() to check for incoming Modbus requests from the master.CONTROLLINO_R0 to CONTROLLINO_R10) are updated based on the data received from the slave’s discrete inputs.CONTROLLINO_D0 to CONTROLLINO_D4) are updated based on the slave’s input registers.You have now successfully established Modbus RTU communication between a CONTROLLINO master and slave. The master reads digital and analog inputs, sends this data to the slave, and controls the slave’s outputs accordingly. Experiment with this setup to synchronize multiple devices or expand your project with additional sensors and actuators!

Also this tutorial can be a base example on how to extend the I/Os of a CONTROLLINO with another CONTROLLINO, using Modbus RTU and RS485.

Introduction In the world of industrial automation, having an intuitive and powerful programming environment is key. OpenPLC Editor, combined with CONTROLLINO, brings a seamless IEC

The project provides an easy to install tool to test the main features of the Controllino MICRO by serving an embedded web application directly from